Login (User Login; top right of page) with your web user or complete this form to download.

Energy Management for Smart Factories

Energy and resource management is playing an increasingly fundamental role for manufacturers. On one hand, increasing energy expenses are becoming noticeable in production costs, and on the other hand, profitable margins can only take effect if costs are reduced.

Manufacturers need approximately 37% of total global energy use in 2017. Although manufacturers are starting to look for green energy solutions, they still face many challenges related to energy management:

- Budget: Poor energy management can lead to high expenses when overloading machines can cause breakdowns or underloading decreases productivity. Manufacturers need to ensure they are minimizing energy usage while maximizing its utility.

- Data collection: Manufacturers cannot make informed decisions if they don't know how much energy each piece of machinery uses and what level of power will lead to optimal functioning. Without IoT technology, data collection requires time-consuming sampling procedures and results in data that cannot be interpreted in real time.

- Government assistance: To receive some kinds of government aid, such as tax incentives, manufacturing organizations in many countries must comply with certain standards for energy efficiency. Without the right tools, meeting government requirements for energy management may be difficult, if not impossible.

Manufacturing companies can resolve these challenges and make more informed decisions if they know how much energy each piece of machinery uses and what level of power will lead to optimal functioning. Energy data management systems (EDMS) based on real-time data from sensors and IoT devices are therefore essential to successful digitalization and the development of Smart Factories.

Energy Data Management with zenon

What does an EDMS do?

An EDMS can support your organization by:

- Collecting energy data from various sources across your infrastructure: A quality EDMS like zenon will gather data on energy usage from all areas of your organization — including production and facility management. An EDMS will automatically collect energy data from equipment regardless of its manufacturer, allowing you to see how efficiently each component is running in one convenient location. zenon can collect data effectively even in factories with decentralized and complex infrastructure.

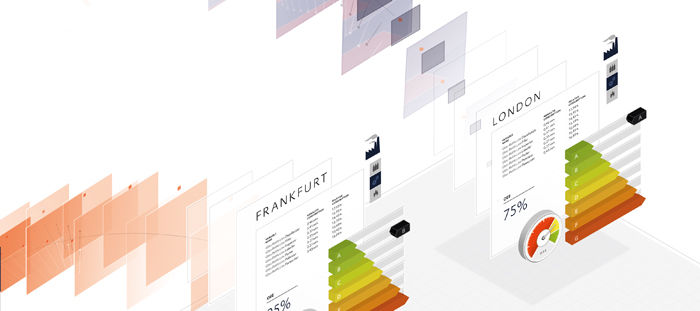

- Providing an overview of energy consumption: An EDMS will collect all your energy usage data in one location, allowing you to see large-scale trends in energy consumption. zenon displays energy data in real time using an easy-to-understand interface. With a clear overview of energy consumption throughout your facility, you can quickly evaluate progress toward your goals.

- Monitoring data of new and existing equipment: Using an EDMS, you can easily monitor and compare the energy consumption of both new and old equipment. Understanding what equipment uses the most energy is key to profitability and making evidence-based purchasing decisions.

- Identifying opportunities to increase equipment efficiency and reduce consumption: An EDMS like zenon makes it easier to analyze energy data and improve equipment efficiency. View trend curves and graphical reports, and consider data in conjunction with productivity and cost. If you notice a piece of equipment is lagging behind in productivity while using more energy than necessary, you can look for ways to replace it or improve its performance, reducing costs.

- Evaluating deviations to ensure error-free energy provision: Every piece of equipment should receive the exact amount of energy necessary to maximize productivity. An EDMS can help you avoid costly errors in energy provision by alerting you to abnormal activity. Depending on the problem, your EDMS may even be able to resolve it automatically, allowing you to focus on other tasks. If the event requires intervention, chronological event list will ensure that you have the information you need to evaluate the deviation’s cause and prevent the error from recurring.

As an EDMS, the zenon Software Platform from COPA-DATA provides critical features that you will need for your Smart Factory energy management, such as Energy Performance Indicators, energy analysis, trend curves, Alarm Message Lists, Chronological Event Lists and many more.

Benefits of successful energy management

zenon will help you collect plant energy data from sensors and other IoT devices to monitor and manage energy consumption across the shop floor in real-time, resulting in more successful energy management efforts. TÜV Süd requirements for certified energy data management are met by the software platform, which is fully compliant with the ISO 50001 standard on monitoring, measurement and analysis. The benefits you can expect from zenon include:

zenon helps you to collect plant energy data from sensors and other IoT devices to monitor and manage energy consumption across the shop floor in real-time. The software platform meets TÜV Süd requirements for certified energy data management and is compliant with the ISO 50001 standard on monitoring, measurement and analysis. The benefits you can expect from zenon include:

- High efficiency: Using the data collected and analyzed by your EDMS based on zenon, you can make decisions that improve energy efficiency and boost productivity. You can even keep machinery running at the optimal voltage for productivity.

- Cost savings: By identifying leakages and other sources of inefficiency to be addressed, as well as avoiding costly power peaks, a successful energy management solution can provide significant cost savings for a manufacturing facility.

- Improved safety: Better energy management can help you increase worker safety by preventing machine overheating and ensuring necessary repairs occur before a malfunctioning system or inadequate power backup leads to an accident.

- Energy reliability: Continuous monitoring of energy usage creates high operational reliability. With real-time measurements and historical data, you can see potential problems and correct them early to prevent unexpected downtime.

Contact COPA-DATA about Smart Factory energy management

From automating data collection and analysis to informing decisions, zenon will support every aspect of your energy management with one unified system. This hardware-independent software platform can be easily integrated into your existing production assets. In addition, zenon meets ISO 50001 standard requirements and comes with a user-friendly graphical interface and robust security features.

We can assist with your energy management project from start to finish and provide solutions tailored to your requirements. To learn more about Smart Factory energy management, contact us today.

Energy Data Management with zenon

Download

1.1 MB

Road to Energy Management System

Poster

Download

5.4 MB

Energy Management - IU 25 Spotlight

IU Magazine Article

Download

2.2 MB