zenon for machine builders

On this site you find:

- Applications and benefits

- Connectivity

- Commissioning

- zenon in operation

- Life cycle and benefits

- How zenon makes a difference

Machine building is an ever-evolving market that constantly sees the emergence of new technologies, security challenges, data demands and more. To remain competitive in the era of Industry 4.0, machine builders need a future-proof machine operating system that meets their changing needs and, ideally, also boost productivity while enhancing the products they offer their customers.

zenon by COPA-DATA is an innovative, secure software platform for the machine building industry. From automated engineering to integrated reporting, discover how original equipment manufacturers (OEMs) can use zenon to transform their customers’ manufacturing operations and grow their businesses.

zenon machine building applications and benefits

The zenon Software Platform comes with a range of features that can help equipment run efficiently in machinery and plant building for many manufacturing industries, including pharmaceutical, food and beverage, automotive and others. When used for machine building, zenon offers unmatched benefits through engineering, commissioning and operation.

Engineering

When using zenon for machine building, engineering tasks become a whole lot easier and more flexible. With zenon, you can increase the scope of your operations according to your customer needs. But how can machine builders benefit from zenon while completing engineering-related duties? There are actually numerous ways zenon can help, with automated engineering, versioning and individual adaption being only a few of zenon's features that assist with the engineering tasks. Learn more about the way our software can help your team handle a variety of engineering operations:

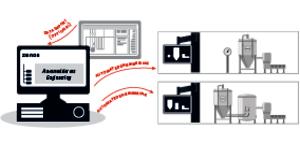

Automated engineering

Automated engineering helps today's machine builders face new challenges, such as customers increasingly demanding customization, while still needing to keep costs down to remain competitive. With zenon, you use automated engineering to visualize and control projects for various versions of machines. This reduces time to market and helps you to stay ahead of the competition.

zenon handles equipment configuration from planning systems in a completely automated manner. The zenon Engineering Studio enables you to automate repetitive tasks such as importing variables and creating graphic elements, significantly reducing the potential for mistakes. Thanks to zenon, complexity is now fully under control.

Modularization

Conventional production equipment is neither flexible nor efficient enough to meet the soaring demand for customer-specific individualization, driven by the introduction of new products and shifting product quantities. This is where zenon comes in. With a modular approach to construction, machine builders can develop process equipment with more options for customizable production.

From version 8.20 on, the zenon Engineering Studio offers Smart Objects, which can be used to make project engineering even simpler. Smart Objects are made up of standardized functional units that go into all module settings and functions needed to map a process component. Once you create your Smart Objects templates, they can be instanced multiple times in your projects, with the links and objects being automatically generated by the software.

The decentralized intelligence for modular applications reduces the engineering work through autonomous equipment modules and helps users react quickly to fluctuating market demands to stay competitive. Another primary benefit of modularization comes down to a module's ability to be used over and over again, without needing to be rewritten. The reuse of existing modules does not require cost-intensive new developments, potentially saving your company time and money.

Versioning

As you are updating projects, zenon automatically generates a comparison of consecutive project versions. These comparisons make it easy to analyze the differences between projects, helping you ensure you include the right features. No external programs are necessary, this service is fully integrated. Furthermore, zenon also passes on changes to external management projects, using open interfaces like XML. By using the versioning features of zenon, you can receive benefits from a more transparent version administration, which allows total traceability of any changes.

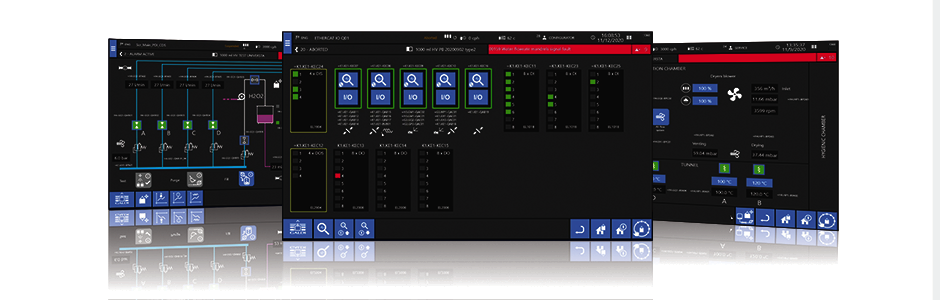

Connectivity

As technology advances, single devices, industrial equipment and even entire factories are becoming more connected. Through the Industrial Internet of Things (IIoT), machines can communicate with each other to increase efficiency, reduce downtime and provide valuable data to operators. Machine builders increasingly need to deliver enhanced connectivity to their customers to allow them to take advantage of these advanced technologies.

zenon helps facilitate this connectivity, as it has its own drivers and protocols and also supports more than 300 communication protocols and open interfaces, which enables it to connect seamlessly with most machines. This allows machines to communicate with each other, as well as other systems, such as enterprise resource planning (ERP) systems. While the customer’s machines communicate with each other, zenon's OPC UA Server ensures that their data remains secure. zenon's OPC UA Server is backed by a certification from the OPC Foundation.

Additionally, zenon can serve as the foundation for networked factories, as machines equipped with zenon can integrate seamlessly and securely into IIoT infrastructures. OEMs can offer this capability to their customers as a way that their equipment outperforms the competition.

Security

Security is crucial to any engineering efforts and industrial operations, and the rise of the Internet of Things (IoT) brings new challenges. At COPA-DATA, we ensure that security is an integral feature of our products, helping companies stay safe throughout a project's lifecycle. zenon features numerous out-of-the-box security features and can integrate with existing security systems. We developed zenon according to the requirements of IEC 62443, a security standard for control system components.

zenon's security features include 128-bit communication encryption, easily configured user authentication and file signature, which enables zenon to recognize manipulated program files. The role-based user administration lets you define the level of access in zenon Engineering Studio and Service Engine for any user in the Active Directory. Changes to the Service Engine can be synchronized with the Engineering Studio remotely in real time. There are 128 different access levels available. You can add as many users as desired.

zenon also offers seamless redundancy, which ensures that no data is lost if a processor breaks down. Even in the time between the breakdown and when the backup server takes over, seamless redundancy ensures zero data loss. Not having to worry about data loss is a huge advantage to your engineering efforts, helping your team recover lost data quickly and stay on schedule. zenon redundancy is also easy to configure. All you have to do is define the server and standby server.

Individual adaptation

With zenon, it's easy to adopt the human-machine interface (HMI), Plant Data Collection (PDC), Line Management or Supervisory Control and Data Acquisition (SCADA) to the individual using it. Users can easily switch between various languages and measuring units. zenon's Unicode support means that the software works with a variety of countries, languages and platforms.

The zenon Engineering Studio user interface is available in different languages, and you can use as many languages as necessary in Service Engine, even in the configuration stage. This capability makes the system more user-friendly and enables cooperation between facilities in various countries.

In addition to switching between languages, zenon can be adapted several other ways to the needs of machine builders. For example, many users enjoy how individual adaptation allows them to switch color palettes when they need to improve visualization. Other popular components of zenon's individual adaptation capabilities include the user's ability to configure dashboards, create their own set of trends and switch the help connection.

Commissioning

During the commissioning process, machine builders need to ensure that their products are properly designed, securely installed, safely tested, correctly operated and responsibly maintained. With zenon, you examine all the various components of the equipment and verify that each piece is operating correctly. If any problems occur within the system, zenon makes it easy to pinpoint the source of the problem. This way, issues can be isolated and rectified before they become costly and reduce the efficiency of your operations.

Learn more about a couple of zenon's top features that facilitate an easier commissioning process:

Network

Horizontal and vertical integration are crucial to the creation of a smart factory and enabling communication between machines and systems across a network. zenon has various features that facilitate horizontal and vertical integration, ensuring that IoT devices, engineering processes and machinery are all working together properly. With the software, you receive easy integration, even in environments with equipment from numerous manufacturers.

With zenon's Hot Reload feature, engineers update projects at any time and activate the changes without shutting down the machine. This enables them to adapt to new information and keep the system updated without losing valuable time due to equipment shutdown.

Integrations with third-party systems

zenon also offers seamless integration with various third-party systems. The certified SAP ERP interface included in zenon, for example, makes it easy to connect the process level with the ERP, providing an overview of the whole organization from order processing to production to delivery. The interface provides two-way communication between zenon and SAP, meaning zenon can provide the ERP with information about processes and receive control instructions from the ERP level as well.

In operation

Easy to set up, integrate, use and maintain, zenon is designed to be as user-friendly as possible so that operators can focus on running their projects. Through features such as user-defined HMIs and Multi-Touch control, operation becomes more intuitive. Reporting comes integrated into zenon, and recipe templates make machine control easier and more efficient.

Find out more about the numerous features that your customer’s can employ using zenon in their daily operations:

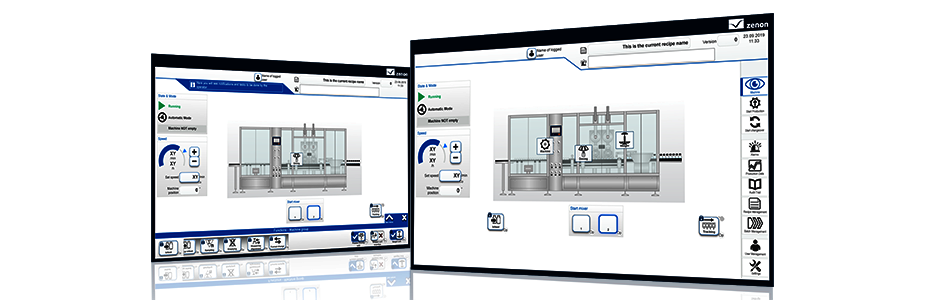

Customizable human-machine interfaces

HMIs serve as the interface between operators and the machines they work with, making them crucial to user-friendly machine operation. As customization becomes more common in the industrial sector, customers increasingly want tailor-made HMIs for their equipment. If a customer approaches a machine builder like you with a specific vision in mind, zenon makes it easy for you to bring that vision to life.

In addition to HMIs tailored to each customer, zenon also allows you to offer user-defined HMIs — the ability to customize the HMI to the needs and preferences of each user. With zenon, users easily change display colors, languages and measuring units and rearrange widgets to customize the dashboard. You can also create different dashboards, with different permissions and setups, for different user levels.

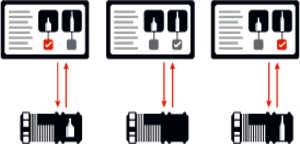

Smart Checklist

The zenon Smart Checklist provides a convenient replacement for the paper list in testing processes. The Smart Checklist in zenon, significantly reduces the possibility of errors because users are required to complete each step fully before moving on. The program also guides them through the checklist according to the ISA-88 standard, making it easier to prove the conformity of a machine. In addition, the feature works on stationary computers, laptops and smartphones, enabling data acquisition from anywhere.

Recipes

Machine manufacturers need flexibility and customization capabilities when it comes to recipes. They may need to make changes frequently to meet the demands of their customers. Custom approaches to recipe management can also help set a given solution apart from the competition.

With zenon, users define how they manage recipes without extra programming or additional software. The program offers templates that enable quick engineering as well as ample flexibility. They can easily set the status of a recipe according to their needs and define own status handling rules. Additionally, they easily import recipes from other systems and export them as needed. Recipe handling in zenon also complies with international safety specifications.

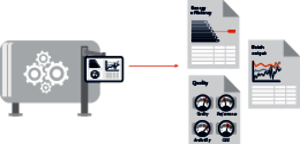

Reporting

Reporting is key to improving plant performance, reducing costs and gaining a competitive advantage. With zenon, machine builders can offer their customers intuitive, customizable reporting with minimal effort.

zenon makes it easy to display important information related to production batches, energy usage and more right on a machine's operating panel. Fully integrated into zenon, operators benefit from tailored reporting with minimal engineering and without additional software tools. Reports are also displayed in an actionable, easy-to-read format, helping operators to improve machine performance.

Some examples of reports that users can easily generate include:

- Statistical Process Control (SPC): SPC reports are used to evaluate and assure quality during production.

- Process Capability: These reports show whether production quality is stable and if production is running within defined limits.

- Control Chart: Control charts display information about the stability of quality during series production. They can help the operator detect product quality variance early in the production process.

- Histogram: These reports are useful for evaluating how stable the output quality of a process is.

- Overall Equipment Effectiveness (OEE) Analysis: With the zenon Analyzer, operators quickly generate reports that calculate key performance indicators (KPIs) for their OEE. They'll set the OEE report to a period of time, and simply adjust it to take into account whatever production equipment they want to analyze.

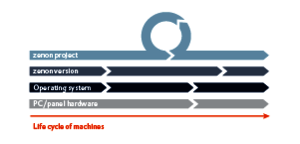

Product life cycle

At COPA-DATA, we're constantly updating our software platform to ensure it keeps up with the ever-changing demands of our core industries. We offer regular updates and also take measures to give users as much flexibility as possible and ensure updates go smoothly. Therefore, we also ensure that all new versions of zenon are compatible with previous versions. This means machines running on the latest version of the software can still communicate with those running an older version.

With zenon, users easily convert projects to the latest version of the software without risk of losses. You can also create projects in the current Engineering Studio that are compatible with older versions. This means that even when you update machines or software, projects can continue to run without interruption.

Additional benefits of using zenon

- Compliance: zenon offers full compliance as standard and meets international standards such as IEC 62443, FDA 21 CFR Part 11 and Annex 11 of the EU GMP guidelines.

- Customer service: COPA-DATA offers training and support services tailored to your industry and use case. Our network of local application engineers, technical consultants, industry experts and partners ensures the best experience for our customers.

- One-stop solution: zenon is a one-stop solution for industrial automation, monitoring, control and analysis. It includes HMI, SCADA, IoT, soft Logic, line management, reporting, alarming and more in one integrated platform.

For machine builders: zenon from COPA-DATA

Since 1987 zenon has set the industrial software standard for machine builders. Building on our extensive experience, we are constantly improving our software to make sure it meets your needs and helps to improve your operations. Contact us today to get started.

How zenon makes a difference

-

Optimum Usability – Efficiently Executed

zenon software has a impressive user-friendly design. Get optimal use out of your automation software with our easy human machine interfaces.

-

Modular Systems via Automated Engineering

Overcome a wide range of challenges with a modular approach to design. zenon software supports this approach to reduce time and maintain efficiency.

-

Access Reporting at the Machine

Get operational reports at the machine level with zenon software. Out automation software measures machine production efficiency.

-

Flexibly Configure Recipes

Create custom recipes for batch manufacturing flexibility with zenon. Learn more about how zenon can give you a competitive advantage through custom solutions.

-

Stay Compatible – across Generations of Machines

zenon machine automation software can support your ageing filling line. Learn more about how our software can be used for both new and older machines.

-

Effective Production Requires Robust Software

Increase factory production with zenon software. Our manufacturing production software reduces bottlenecks and increases reliability.

-

Machine to Machine Communication

zenon software enables machine to machine communication which helps avoid unnecessary detours and saves time during production. Learn more today.

-

The Secure Route to the Smart Factory

Maintain smart factory cyber security with the help of zenon Software Platform. Learn more about how zenon can protect critical operation tasks.