The BrauBeviale booth for your Net Zero transformation

The F&B industry, like all industries worldwide, is in the midst of the Net Zero transformation. This transformation affects traditional brands, the inventive machine-building industry, as well as newly emerging manufacturers or small labels and suppliers. Is this a positive or negative change? Is it self-selected or forced? In any case, it is necessary and basically normal: progress requires change.

Start the transformation journey courageously and positively

The food and beverage industry is open and ready for change, and COPA-DATA's zenon software platform offers a comprehensive tool for shaping sustainable business through innovation and digitalization. This involves numerous solutions across the entire production plant and various disciplines - from flexible process automation to holistic monitoring, from data acquisition to complex analytics, from energy management to in-house production of renewable energy.

Both plant manufacturers (OEMs) and beverage producers will gain new impetus for innovative solutions at the COPA-DATA stand. "Most of our customers are already on their own individual journey to more sustainability in their business. Digitalization is a real accelerator and enabler in this process, in order to retain the necessary innovative strength at the same time. We develop new solutions every day to master these challenges in a commercially attractive way, both as an OEM and as a beverage manufacturer. In doing so, we want to create a 'Happy Transformation Journey' with our customers. Stop by Hall 7, Stand 421," says Emilian Axinia, Director Industry Management Sustainability Solutions and F&B at COPA-DATA.

A platform with countless solutions

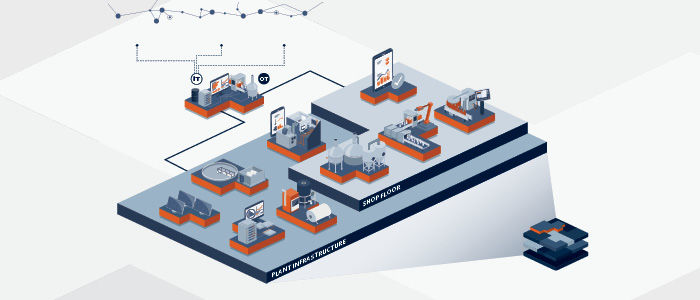

For years, the zenon software platform has been a bridging technology between the two mindsets of "never change a running system" (OT) and "continuous improvement" (IT). Today, in times of numerous Net Zero initiatives, the focus is clearly set for cooperation between OT and IT and the implementation of concrete sustainability goals. Thus, when used as Plant Information Management in the food and beverage industry, zenon can guarantee the Weihenstephan standards with OPC UA Companion, function as a central control room with comprehensive HTML5 plant dashboards, and precisely record and store production data using Plant Historian.

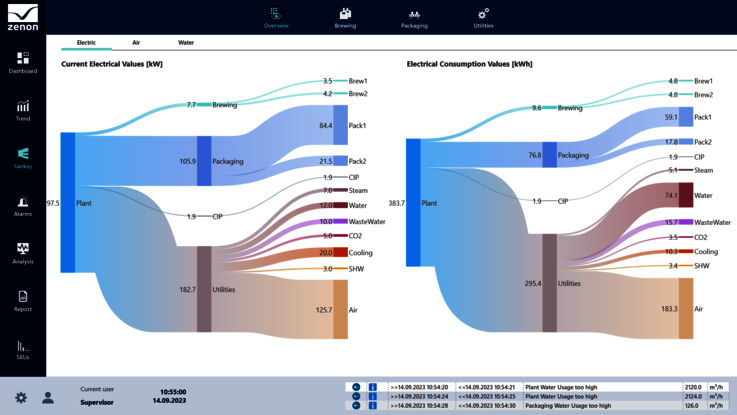

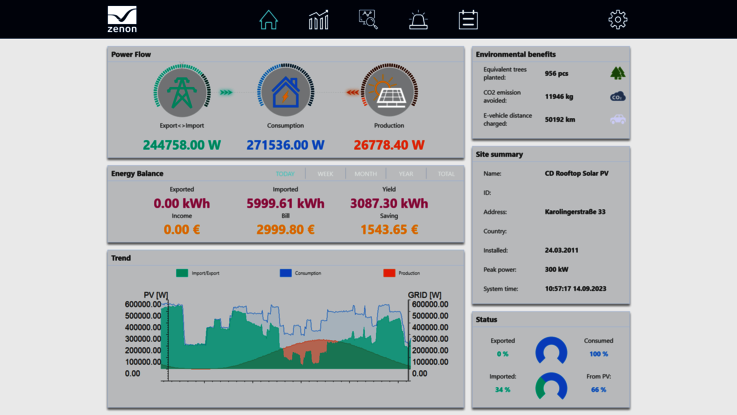

As an energy data management system, zenon can map all forms of energy flows within a production. Similarly, it can monitor production-essential utilities, visualize and control power generation and distribution from its own renewable energy sources, and assess their impact on the carbon footprint. Look forward to a new solution with the company SMC on the subject of air management at the COPA-DATA booth 421 in hall 7.

Innovative new developments for the brewing industry

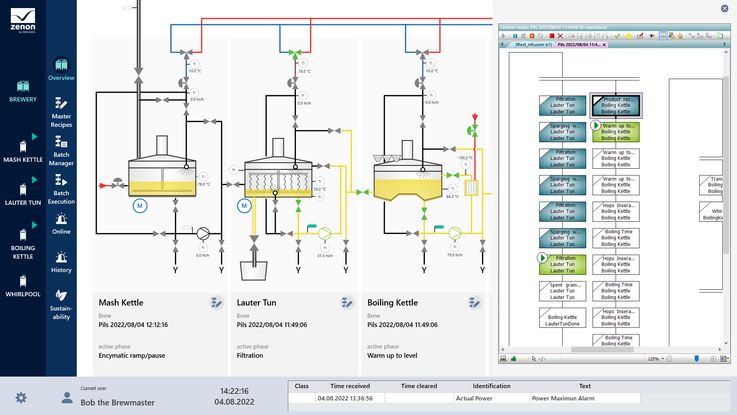

As a brewer, you will probably be interested not only in the line management scenarios with zenon that have already been used many times but also in the concrete application for brewing automation including the cleaning-in-place process (CIP). In combination with modular automation according to the standard Module Type Package (MTP), a technological innovation can be examined here for the first time. A joint demo with Beckhoff can be found at the stand. And of course, other solution options from COPA-DATA are waiting to be discovered by you. All zenon solutions have the charm that it is not only about the visualization and transparent presentation of production data but can also be actively controlled by means of zenon, thus allowing processes to be directly optimized.

What's in it for OEM customers?

For OEM customers, zenon as premium HMI software, offers news around the latest OMAC PackML guidelines. Examples are also shown of how an HMI operator can experience more involvement in higher-level sustainability goals. The COPA-DATA team will also be happy to show you how easy it can be to adapt line control and the associated integration into digital architectures by means of a modular structure of the software platform itself. Plant builders will find out more about modular process control according to ISA 88 and the new MTP standard at booth 421 in hall 7.

Emilian Axinia and his team will be happy to show you new ways for more Net Zero transparency and interdisciplinarity with the zenon software platform. Furthermore they will help to facilitate elaborate change processes, making them clearer and more agile. If you are willing to make your transformation journey a "happy" one, you are cordially invited to visit the COPA-DATA team at BrauBeviale in Hall 7, booth 421.

Your free ticket

You don't have a BrauBeviale ticket yet? We can reserve one free ticket per event day for you. Please contact our event team (events@copadata.com) and let us know on which day you would like to visit us at BrauBeviale.

We are looking to forward to seeing you!

Read more about Net Zero opportunities with zenon and how Emilian Axinia has perceived the connections between sustainability, innovation and digitalization in exciting customer projects in his articles on our Melting Blog.

Back