How module type package helps companies stay ahead of the competition with modular production

Product and innovation cycles are getting shorter and shorter, thanks to an increased demand for small batches and individualized solutions. Reduced production and innovation times can be a problem for manufacturers, particularly those in the pharmaceutical and process manufacturing industries. The process plants used in these industries and by cosmetic companies and food producers are usually not set up to be flexible enough to adapt and change on short notice.

Enter modular production, which simplifies the process of changing production quantities or adapting equipment to produce new products or formulations. Modular production breaks up large tasks into several smaller components. Production splits up into individual services, and each service is standardized. Since each module is interconnected, multiple configuration possibilities exist. Manufacturers can "plug and produce," changing configurations as needed based on the product being created.

Modular production and module type package (MTP) provide a high-performance solution that has revolutionized production across multiple industries. Before examining the benefits of MTP and modular production, take a closer look at the challenges manufacturers face with agile production.

Production challenges for manufacturers

Whether in the process, pharmaceutical, chemical, or food and beverage industry, today's manufacturers are up against numerous challenges, affecting their ability to produce products and get those products to clients while earning a profit.

Increased competition

Competition is high for manufacturers globally. Today's manufacturers need to compete with each other on price and productivity. How much they pay the people who work for them also affects their competitiveness. For example, U.S.-based companies might find it challenging to keep up with costs, mainly as manufacturers in other countries pay employees much less than American workers. In the U.K., an ongoing labor shortage could make it challenging for British manufacturers to compete on a global scale.

Another area of competition is in output. Some manufacturers can produce more products more quickly than others.

To get ahead and stay ahead, manufacturers should focus on the following areas:

- Building a solid brand and good reputation

- Improving price competitiveness without negatively affecting the bottom line

- Using technology to enhance innovation

High production costs

Many manufacturers face two issues that directly contribute to high production costs: supply chain disruptions and labor shortages. Production costs include the price of materials, labor cost and any overhead associated with running a factory. In some cases, production costs can be out of the control of a manufacturer. For example, inflation or supply chain disruptions can lead to increases in the price of materials, which increase a company's production costs.

Labor shortages can also increase production costs. When there are more openings than workers, companies often need to increase the amount they pay employees to make the positions more attractive. Labor shortages also increase production costs, as production slows down when there aren't enough people on the factory floor.

Fortunately, there are ways to lower production costs. If supply chain issues keep a company from getting the appropriate materials, it can consider substitute options that are more readily available. Modular production methods also increase flexibility which can lead to lower costs.

Shorter product life cycles

Product life cycles are shrinking, which can present a challenge to manufacturers. Manufacturers often invest a considerable amount of time and money into producing a new product, only for that product to move off of the market within a few years. Companies then need to market and manufacture a new product, spending more time and money. Shorter product life cycles can adversely affect manufacturers in the following ways:

- Reduced opportunity to earn a profit

- Increased difficulty forecasting a product's performance

- Reduced flexibility and little room for mistakes

Adopting a small batch production process allows manufacturers to adjust and adapt to reduced product life cycles.

Increased demand for customized products

Personalization and customization are popular, which can be good news for companies seeking to differentiate themselves from the competition but challenging for manufacturers that need to produce customized products. It's no longer enough for a company to manufacture the same white-label product and for companies to put their branding on it. Now, that product needs to be different from the rest.

Older manufacturing methods make it difficult for factories to adjust and adapt production as needed to accommodate a broader range of custom products. MTP and modular production make it easier for manufacturers to change the configuration of their factories to allow for the production of various products.

Advantages of modular production for manufacturers

The obstacles today's manufacturers face can affect their profitability and relationships with clients. Adopting a modular production process allows manufacturers to confront many of their challenges, offering several notable benefits.

Increase innovation capability

Increased competition means that companies need to get more innovative to stay relevant and keep customers coming back for more. That means that many companies feel compelled to introduce new product lines or variations on their most popular products regularly.

Think flavored versions of soda, different varieties of sandwich cookies and new lipstick or blush colors. Pharmaceutical companies adjust the formula of drugs or supplements to keep their patents fresh. Automotive companies introduce new models and designs of their most popular vehicles. Every time a company introduces a new product or spin-off, the manufacturing process needs to change.

With modularization, a manufacturer can significantly reduce investment risk. It can change the production capacity of the new product based on market demand. For instance, if a new soda flavor proves to be more popular than the original, a company that's embraced modular production can adjust its factories to increase production of the new, more popular product. Modularization helps manufacturers remain competitive.

Reduce production costs by 40%

Traditional manufacturing methods cost a considerable amount of time and money to alter plant layout when switching products. With modular production, costs can drop by 40%, allowing for greater flexibility. The reduced production costs are particularly notable when a plant produces small batches of each object.

Modular production and MTP streamline the transition from one manufacturing process to another. A plant can dedicate the first two days of a week to producing Product A, then switch to Product B for one day. They can then transition the setup to allow for the production of Product C during the remaining two days of the week, all without having to spend hours and considerable sums of money making the switch.

Decrease time to market by 50%

Short product life cycles call for a shorter time to market. The faster a company gets a new product on there, the faster it can gauge the product's success. If the product does well, the company can continue to make and sell it. If it's a flop, the company can scrap the product and move on to the next option.

A modular production method reduces time to market by 50% because it relies on prefabricated modules. Engineers can integrate the modules into the process control system with minimal expense. It also takes less time to develop products using a modular method, as it becomes much easier to transition from the lab or development phase to the production phase.

Maximum production flexibility

Plants become more flexible with the introduction of modular production. Engineers can easily swap one module for another when changing the production process without re-engineering or altering their operations. The modular units can also be re-used as needed.

Modular production also gives manufacturers greater freedom in choosing the machines they use. Traditional methods call for using the machines from particular companies or using all of the same equipment. That's no longer required with a modular production process.

What is a modular type package?

Modular type package, or MTP, allows for interoperability by creating a framework for equipment data models to use. MTP functionally describes process properties and interfaces without regard for the technology or manufacturer. This allows various modules to be interconnected and re-used with ease, even if different producers make them.

The modules contain functionalities that reduce their dependence on each other. One way to illustrate how MTP works is to consider a home computer and printer. The two can work together, even if the same manufacturer doesn't produce them. Various models of printers work with multiple models of computers because each type of printer comes with a driver. A user installs the printer driver on their home computer. The driver gives the computer the information it needs to operate the printer.

In this case, the printer is the module, the driver the MTP and the computer the process control. If the printer breaks down or a person wants to switch from a color to a black and white device, they only need to replace or change the module and the MTP, not the process control.

All information provided by an MTP is in a standardized format, facilitating integration into a superordinate Process Orchestration Layer (POL). zenon POL and the zenon Engineering Studio interlock in a fully automated manner here. All work steps are thus automated in the Engineering Studio and transferred to the Service Engine via the POL, resulting in a fully automatically generated process control system (DCS) in just a few steps.

The majority of engineering already incorporates modular engineering. Subsequently, the integration of fully automated modules into the process control system won't require significant outlay.

All MTP-capable modules and their statuses can be managed via zenon Process Equipment Assembly (PEA). This provides an overview of the modules currently integrated into a POL and which are available for use.

The process of MTP production

The MPT production process typically goes like this:

- MTP import: The MTP contains information in a standardized format. MTPs are engineered to contain information that defines the technology interfaces and create the control images and control logic. The MTP gets imported into the process orchestration layer, such as zenon POL.

- Configuration: After importation, the MTP needs to be configured. Service parameters get established, and logistical links are created.

- ISA 88 recipe creation and interconnection: The International Society of Automation (ISA) created ISA 88 to define models and terms concerning batch control. The goal of ISA 88 is to allow automation suppliers to communicate, configure and integrate batches more easily. Many manufacturers use ISA 88 to track batch production. With MTP, the concept of ISA 888 advances into an open vendor, independent plug-and-produce model.

- Testing and production: The final step in the process is testing to ensure that the MTP is correctly integrated within the POL. One way to think of this is to compare it to printing a test page after configuring a new printer. If the test page prints and everything looks good, you can proceed to print the documents you need.

Industries that can benefit from modular production

Any industry that manufactures products can benefit from modular production. Among the industries that stand to benefit the most from modular production are those that produce a wide range of products and those that must follow strict regulatory requirements.

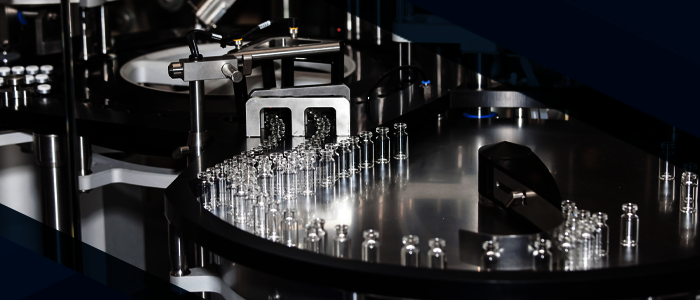

Pharmaceutical manufacturing

Pharmaceutical manufacturers operate in a highly regulated industry, requiring constant monitoring to ensure compliance with standards. Many manufacturers also produce multiple types of medications and treatment products, requiring production agility and flexibility. A plant might need to produce Drug A one week and Drug B the next. Or, depending on demand, a plant might need to shift its production schedule. For example, in the winter months, a plant might need to focus on producing flu vaccines over other products.

Companies that manufacture pharmaceuticals benefit from modular production as it allows them to pivot as needed. They can easily program the equipment to produce different medications or products while reducing the risk of cross-contamination and other safety issues.

Chemical

Similarly, companies that produce chemicals, those used in cleaning products, medical products or dyes, need to comply with regulations while also remaining flexible. A modular production process allows a chemical plant to adjust its production schedules based on demand for its various products.

Water and waste

Plants that process waste and water or that contribute to energy infrastructure can also benefit from modular production. MTP and modular production allow these plants to be flexible, cut costs and maintain security.

Process

The process industry often uses a specific formula to combine raw materials and supplies into goods, such as cosmetics, plastics, chemicals and food products. Typically, the goods created in the process industry follow a specific recipe, and once they are made, they can't be broken down into their individual components once again.

In many cases, a slight tweak to a formula or recipe can mean substantial changes to the manufacturing process for a particular good or product. Modular production allows the process industry to make adjustments as needed without considerable expense.

Food and beverage

Food and beverage companies are constantly introducing new products, and manufacturers need to keep up with shorter product life cycles and greater variety on the market. Modular production allows them to do so by eliminating the need to completely reconfigure equipment every time a new product is created or an older product gets retired.

Learn how zenon can help simplify your modulation production process

COPA-DATA has been committed to simplifying processes with digital and automation solutions for over 30 years. We draw on our extensive experience to continuously advance the zenon Software Platform. You can rely on us to meet your modular production requirements both now and in the future. When well thought through, modularization via MTP can revolutionize the process manufacturing sector and make it competitive for the future. Get in touch with us today to find out more about zenon.