Login (User Login; top right of page) with your web user or complete this form to download.

Crystal clear benefits in production automation at Sklostroj Kempten (Germany)

Highlights:

- Inserted modules: Historian, Extended Trend, Recipegroup Manager

- Used plug-ins for advanced visualization: user administration, language table, measurement unit shift, skins

- Timing system integrated in zenon as .NET plug-in

- zenon Web Server Pro Light as client access

- Remote maintenance via VPN connection

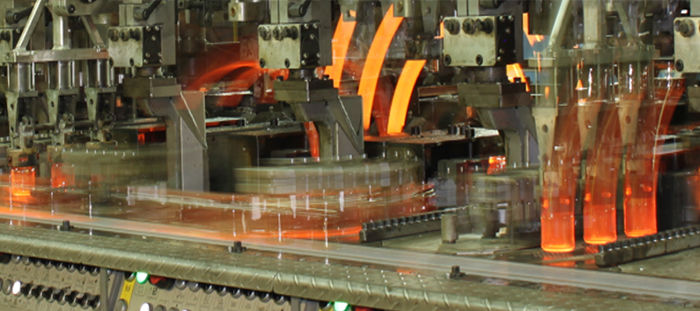

Sklostroj manufactures what are known as IS-machines (individual section). These machines have individual sections arranged side by side, each of which works separately to press hot glass into shape before cooling it down. This process can be employed to produce bottles and glasses of almost any shape and size.

Data is collected permanently in automated production, recording the pressure in the machines, the temperature, and similar variables, for example. Once collected, the data is used to monitor production and, if used correctly, can significantly increase operational efficiency. Each of these numbers corresponds to a variable. Approximately 23,850 variables are captured per cycle in each section of the machines at Sklostroj. In the case of a standard machine with twelve sections, this equates to a total of approximately 286,200 variables.

Günter Zodel, Head of Software Development at Sklostroj Kempten GmbH: “We chose to take a radical step because the huge data volumes frequently overloaded our old visualization system and we were already looking for a more intuitive and modern user interface. We wanted to find a completely new HMI for our machines.” Despite involving changing over an entire system, the project had to be completed quickly. “This is why we chose strong partners to help us,” explains Günter Zodel. "COPA-DATA developed the HMI for us and KROPF took care of implementation into our machines."

Stable processing of huge data volumes

The implementation of the project posed Sklostroj with three challenges: First, every product has its own “recipe”, making its manufacture highly individual. What this means is that the composition of the raw materials, pressure, and time in the station vary depending on the glass or bottle and must be reset every time before commencing production. These settings have to be managed with a recipe system and a timing system. Moreover, the recipes are stored in a central archive and need to be accessible to the operator or retrievable automatically from the machine.

Second, a huge amount of data has to be processed at high speed during live operation. The machines have a central controller to manage all of their functions: the various pneumatic and proportional valves, the servo drives, stepper motors, pushers, etc. As part of this process, a huge amount of data is captured and has to be evaluated and then displayed in the user interface in a user-friendly way.

So that the machine user is able to retain perspective, the third challenge lies in ensuring that the HMI is totally transparent and, above all, stable. Capturing so much information in such a short time pushes an HMI system to the limits of its stability. Sklostroj was, therefore, looking for an HMI that would be able to meet these technical requirements and at the same time appeal to the eye of its users.

Strong partners for project delivery

Sklostroj chose zenon for the visualization software. Despite the high data volume, the system is stable in operation and, most importantly, works intuitively. The user interface is virtually self-explanatory, so end users do not have to complete extensive training. “Ultimately that's what matters to the customers who buy our machines – it's how they evaluate user-friendliness,” says Günter Zodel, explaining why zenon was selected.

“As well as changing over to a new system, this project had a second aim. Our machines had reached their limits where data processing was concerned, but not with regard to mechanics. If the new software could open up so many new possibilities to us, could we take the hardware to the next level as well? So this is what we succeeded in doing,” Zodel continues.

Project partner KROPF Solutions was present on site at Sklostroj to implement the system in the machines. Adrian Olschowka, Head of IT at KROPF Solutions: “Because it's an open system, zenon offers an unbelievable amount of leeway and flexibility where integration into an existing infrastructure is concerned. We can implement this software in almost any environment. Since with zenon the number of variables that can be processed can be doubled compared to the predecessor version, Sklostroj was ultimately able to double the capacity of the glass molding machines too.”

Machine use offline and online – even on the move with WLAN

The first stage of the project initially involved installing the software in the existing 12-section machines. The visualization software was soon processing the captured data, displaying it in a transparent way, and archiving it. The various recipes for the different bottles or glasses are created in the “Recipegroup Manager” module. They are saved in the Historian, from where they can be retrieved by the machines.

This ensures that every container in the station is shaped for exactly the right time and at the right pressure and temperature. This “recipe” is easy to retrieve from the archive if a bottle needs to be manufactured again having not been in production for a period of time. Production of the corresponding product can resume immediately. Data transfer from archive to machine is even possible in offline mode via a laptop or a data medium. As such, production is not dependent on WLAN and network quality. Remote maintenance of the stations can be performed via the VPN connection.

A resilient system for double the capacity

Having found a stable system for the high number of variables, Sklostroj was able to proceed to the second stage and check the extent to which the capacity of a machine could be increased without the resulting data volumes overloading the system. The result is a glass molding machine with double the capacity: a tandem machine with 24 sections in which almost 600,000 variables can be processed.

Since 2014, every machine delivered by Sklostroj has featured zenon. The system is stable in operation and can be relied upon by users for easy and intuitive operation. The data captured is displayed in schematics that are readily understandable. There are various views. The data can be displayed in near real time or as an extended trend, for example. The use of the zenon Web Server Pro Light web client in conjunction with a WLAN control terminal means that mobile working in production is also possible with a tablet or laptop. The plug-in for central user administration enables different authorizations to be assigned to a variety of users. This means that users can only access and call up the machine functions and information that are relevant to them. The user interface supports eight languages – even the data-measuring units can be customized. Access is either via a separate password or linked to the normal operating system.

Highlights:

- Inserted modules: Historian, Extended Trend, Recipegroup Manager

- Used plug-ins for advanced visualization: user administration, language table, measurement unit shift, skins

- Timing system integrated in zenon as .NET plug-in

- zenon Web Server Pro Light as client access

- Remote maintenance via VPN connection