Login (User Login; top right of page) with your web user or complete this form to download.

Incom Leone achieves cost savings with zenon (Slovenia)

Incom Leone achieves cost savings with zenon (Slovenia)

.pdf / 950.95 KB

descargar

Prihranek stroškov z zenonom v proizvodnji sladoleda Incom Leone (Slovenija)

.pdf / 945.10 KB

descargarHighlights:

- Central data collection from production lines

- Error notification enables timely responses

- Eliminating downtime and reducing production costs

- Optimizing machine performance

- SCADA system upgrade option thanks to zenon flexibility

- Simplified design due to zenon parameterization

- Foundations for future energy optimization

Incom Leone is a fast-growing Slovenian ice cream and chocolate manufacturer. Its success and international growth are based on continuous innovation, development and optimization. Much of the company's services are provided inhouse. The company's headquarters in Ajdovščina is home to a technical laboratory and a modern metal workshop where Incom Leone manufactures machines and machine parts for use in its ice cream production.

The company employs around 700 people. Together, they produce around 130 tonnes of ice cream each day. Of the 20 production lines, 13 are dedicated to ice cream. Five produce the chocolate which the company needs for its own ice cream. Two further production lines make chocolate confectionery for sale, including protein chocolate drops and licensed chocolates.

The need for digitalization

A SCADA system was already in use in production to collect data from the production lines but it had a significant drawback: it only communicated with controllers from the same manufacturer. As a result, digitalization initiatives couldn’t progress from their infancy. Processes were automated but the devices were not connected to a common network for process control or efficient data collection. Incom Leone therefore needed a universal SCADA system for control and data collection that could be connected to machines from different manufacturers across its production lines.

Effective controls to ensure product quality

“As a development-oriented company, with continual development of products, processes and technologies, it is important to have precise and continuous control of processes, especially those that depend on several different variables,” explains Rok Slokar, Technical Manager at Incom Leone. “zenon enables just that. It is responsive, resilient and brings flexibility to our processes.”

Freedom to work with or without local partners

When choosing a SCADA system, it was also important to Incom Leone’s engineers and programmers that they could adapt and upgrade the SCADA for themselves. This way, they can keep up with changes in technology and processes without being dependent on external contractors.

Nevertheless, Incom Leone also wanted to be able to work with a local partner with system expertise. The official representative for COPA-DATA's zenon software platform in Slovenia is EXOR ETI. Incom Leone chose to work with EXOR ETI as a partner and its support has enabled faster progress, says the Incom Leone team.

Major savings and process efficiency

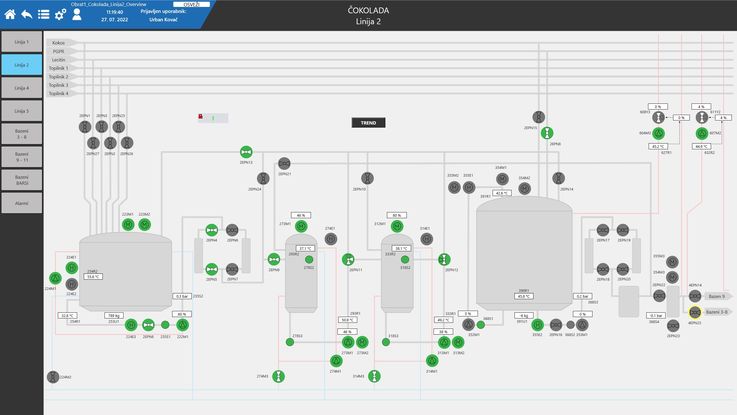

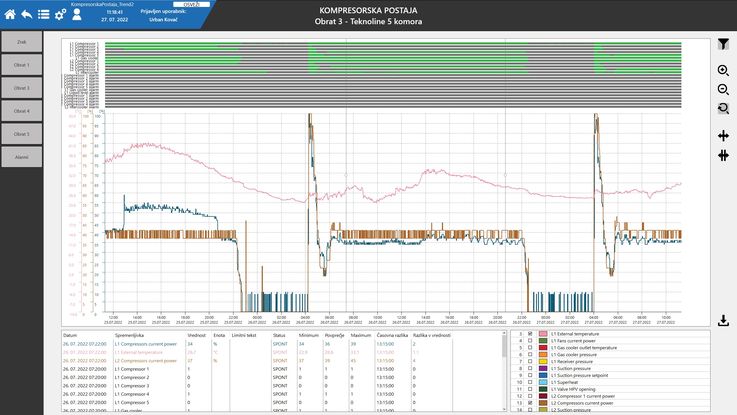

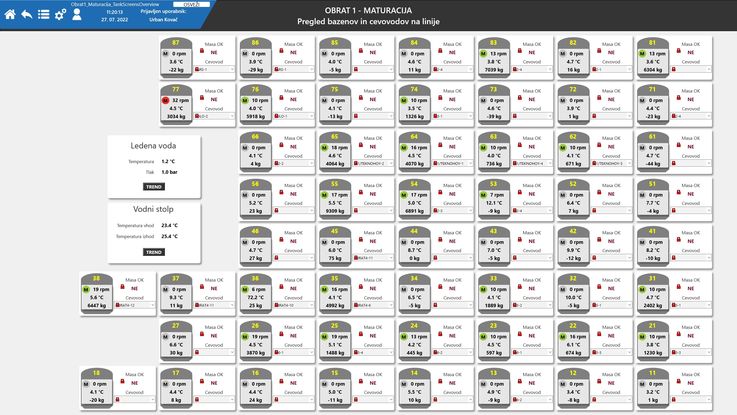

Thanks to the simultaneous monitoring of all machines, the Incom Leone team can now see correlations between the operation of individual machines. Based on data collected from machines and using trend analysis in zenon, the team can clearly identify where anomalies are occurring and investigate their causes. By adjusting hardware settings and software parameters, the engineering team can easily resolve any problems.

Moving towards further digitalization

However, this is far from the end of the line for the company in terms of digitization. The zenon project has heightened the Incom Leone team’s awareness of the potential of digitalization.

Digitalization is now perceived as an important business goal that can power continual improvement. Incom Leone adds at least one new production line every year, so there is always room for learning and improvement. Efficient energy management is a key part of Incom Leone process optimization – and it will be an area of particular focus in the future, with the help of zenon.

Back